Preparing and Finishing Decorative Concrete Floors

One Foot at a Time!

We had our concrete porch floor refinished by HD Epoxy. The result is beautiful; it’s like we have a brand new floor!

A great painting contractor. It’s a family affair with the father, sons and many employees working together.

Epoxy Floor Systems allow you to add a durable abrasion resistant floor that’s easy to clean and is a stunning decorative touch to any room.

Flooring is a crucial part of any interior — whether it’s residential, commercial or industrial. The first physical contact we have with a space is the flooring. It serves as a foundation to the overall ambience of a space. In your own space, you’ve probably decided that your flooring must withstand constant use while maintaining its appearance. With the vast variety of flooring choices available, you have also probably come to conclusion that Epoxy is a practical solution.

For Residential and Commercial Use

For the ultimate in durability and for withstanding any wear & tear, an epoxy floor will do the job. Epoxy floors are incredibly easy to

clean and maintain, from mopping to power washing.

Epoxy floors are inherently incredibly durable, able to withstand heavy traffic for years. If your area requires a low-VOC solution, an anti-microbial surface, stain and/or chemical resistance or a non-slip surface, epoxy floors will deliver.

Typical Applications Include:

- Garages

- Basements

- Kitchens

- Daycares

- Schools

- Medical Facilities

- Churches

- Shopping Malls

- Workshops

- Entranceways

- Community Centres

- Showrooms

- Aircraft Hangers

- Laboratories & Clean Rooms

- Automobile Service Areas

- Sport Complexes

- Exhibition Halls

- Museums

- Grocery Stores

- Retail Stores

- Wet or Dry Processing Areas

- Public Restrooms

- Airports

- Restaurants and Bars

Why Epoxy Floors?

Epoxy Floors are seamless and can be steam cleaned making them very easy to clean, antimicrobial, and hygienic. They are easy to clean and maintain allowing you to keep bacterial levels at a minimum.

Epoxy Floors are long lasting, durable, hard and abrasion resistant. They don’t even require polishing or buffing to maintain. Pigments, Flakes, and Quartz come in a wide array of colours allowing you to customize the look of the floor to your room. Marble Floors are very unique allowing you to create a one of a kind look.

Mesh logos can be added during the floor application process creating a personalized touch for you or your business.

Epoxy Floor Systems

Choose Your Floor

-

Vinyl Flake

Vinyl Flake -

Quartz

Quartz -

Marble/Metal

Marble/Metal -

Solid Colour

Solid Colour -

Polished Concrete

Polished Concrete

Vinyl Flake (Chip) Floor System

Is a durable, seamless, chemical resistant floor providing adjustable levels of slight texture and colour to match any design theme or surrounding.

- Wide Array of Colours

- Durable – Hard and Abrasion Resistant

- Seamless & Hygienic

- Ease of Maintenance

- Stain and Chemical Resistant

Typical Applications:

- Public Areas

- Grocery Stores

- Airports

- Showrooms

- Kitchens

- Garages

- Retail Stores

- Theme Parks

- Hospitality

- Automobile Showrooms

- Schools/Daycares

Quartz Floor System

Is a durable, seamless, chemical resistant floor providing adjustable levels of slight texture and colour to match any design.

- Wide Array of Colours

- Durable – Hard and Abrasion Resistant

- Seamless & Hygienic

- Satin or Gloss Finish

- Ease of Maintenance

- Stain and Chemical Resistant

- Anti-Microbial

Typical Applications:

- Commercial Kitchens

- Public Restrooms

- Wet or Dry Processing Areas

- Grocery Stores

- Airports

- Automotive Services Areas

- Medical Facilities

- Schools / Daycares

- Automotive Showrooms

Marble Floor System

Is a unique floor where multiple colours and metallic epoxy effects are blended to create a stunning visual appeal with the same durability.

- Wide Array of Colours

- Durable – Hard and Abrasion Resistant

- Seamless & Hygienic

- Satin or Gloss Finish

- Ease of Maintenance

- Stain and Chemical Resistant

- Anti-Microbial

Typical Applications:

- Retail Stores

- Shopping Malls

- Automotive Showrooms

- Restaurants & Bars

- Hotels & Casinos

- Art Galleries & Museums

- Collegiate & Professional

- Entranceways

HS Epoxy Floor System (solid colours)

Is a durable epoxy floor that can be customized by picking from a wide array of colour pigments.

- Wide Array of Colours

- Durable – Hard and Abrasion Resistant

- Seamless & Hygienic

- Ease of Maintenance

- Stain and Chemical Resistant

- Anti-Microbial

Typical Applications:

- Warehouses

- Manufacturing Areas

- Laboratories & Clean Rooms

- Automotive Service Areas

- Schools / Daycares

- Exhibition Halls

- Medical & Educational Facilities

- Aircraft Hangers

- Entranceways

- Garages

Polished Concrete

Polished concrete is a modern variety of floor finish that offers high durability with a long life span, is very cost-effective, and is easy to maintain. It is most suitable for places exposed to high traffic and load stress as it offers anti-slip, chemical resistance.

In this process the floor is ground to bring out exposure then a densifier is applied to strengthen the surface bond at molecular level and then polished with high pressure to bring out the gloss finish. It is customizable to bring out the grain exposure in the concrete to customer preference.

Process

Industrial Floor Grinders are used to prepare concrete surfaces prior to the application of new coatings. Grinding concrete can help to remove old coatings, chemicals, adhesive residues and stains to create a smooth clean flat concrete surface.

H.D. Process

Each Floor begins with diamond grinding the concrete to ensure the epoxy has the right surface to properly adhere to. Cracks and joints are filled and sealed to create a solid surface. A bond coat is applied as a first coat to seal the entire floor. A second bond coat is then applied.

Optional Add-ons

- Concrete sealing

- Add anti-slip additives

- Embed your logo

- Add cove moulding to provide a seamless interface between walls and floor.

- Other add-ons include: Moisture Vapour Barrier, Polyurethane Top Coats, Silica Aggregate, Stairs.

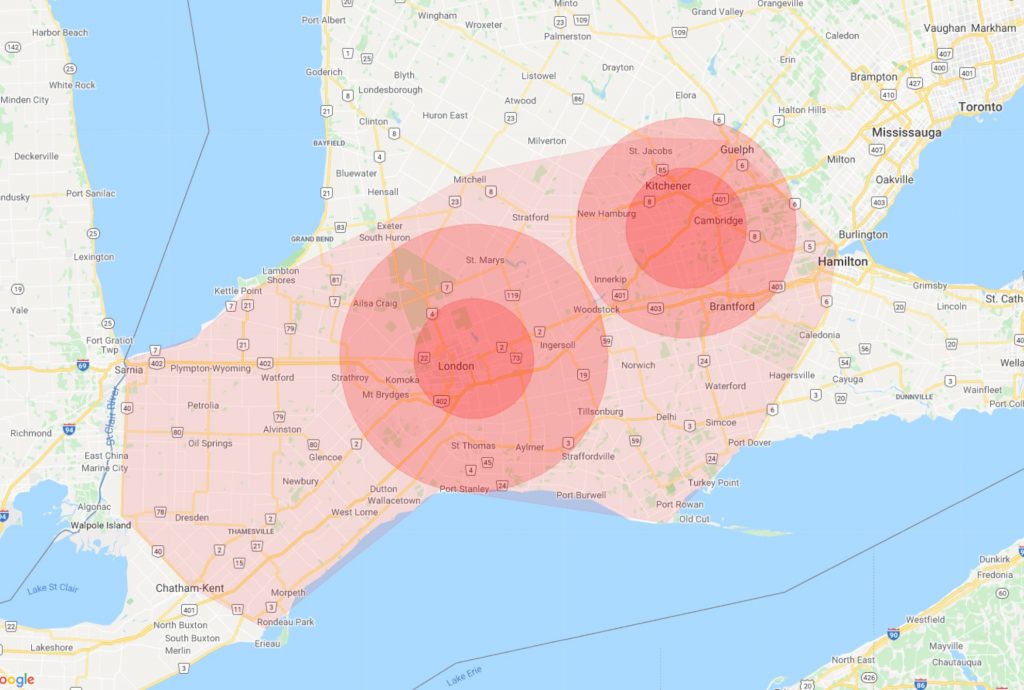

Service Coverage Area